AIKEN, S.C. — Employees at the Savannah River Site (SRS) have successfully developed a solution to improve the processing of spent nuclear fuel, significantly reducing the time required for permanent disposal.

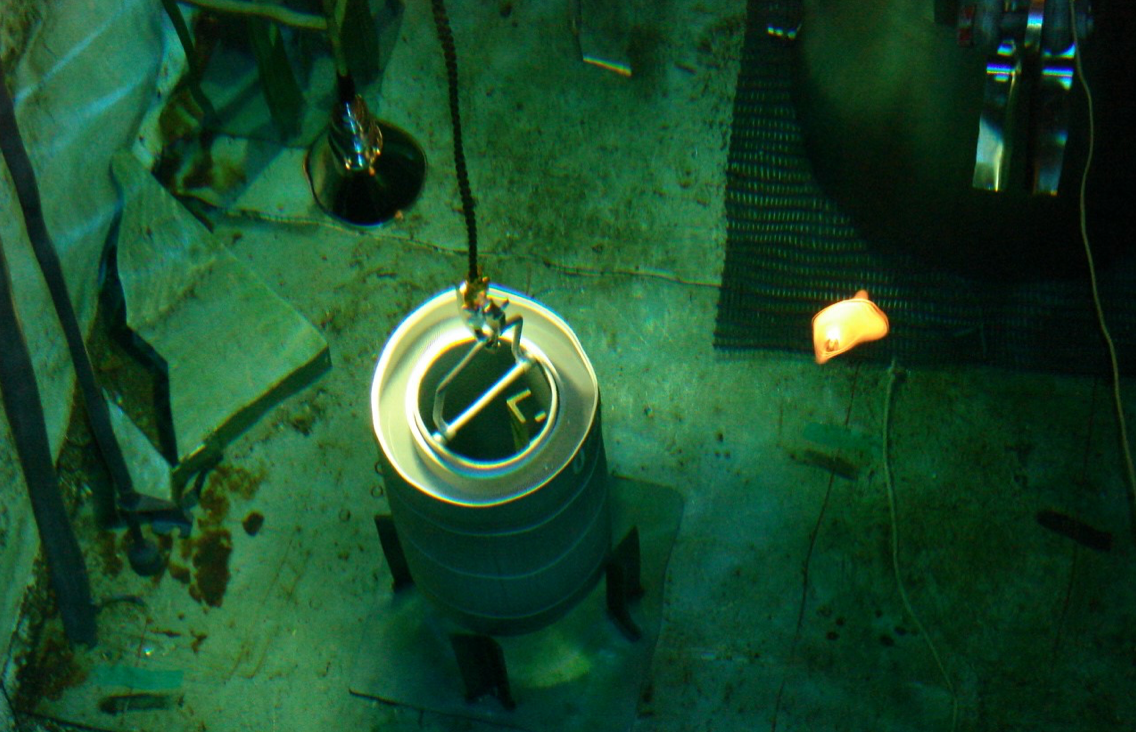

Engineers and operators redesigned the carriers used to transport a special type of spent fuel stored in an underwater basin at the site, improving efficiency for future processing, according to a press release from SRS.

The newly designed carriers, made from a more dissolvable aluminum alloy, allow for quicker processing of spent nuclear fuel, which is sent to SRS from the High Flux Isotope Reactor (HFIR) at Oak Ridge National Laboratory in Tennessee.

HFIR is a leading U.S. neutron source for research and uses highly enriched uranium, according to a press release from SRS.

As part of the Accelerated Basin De-inventory approach, SRS engineers now send the fuel to the H Canyon chemical separations facility, where it is dissolved and eventually vitrified for safe storage.

This improvement is expected to accelerate the fuel disposition by over 20 years and save more than $4 billion in the process.

The HFIR fuel is distinct from other types, shaped in cylindrical cores rather than long tubes or bundles. Special carriers, designed to hold these cores, are used to transport the material underwater to awaiting casks and rail cars.

Once at H Canyon, the fuel undergoes dissolution, where it is submerged in a nitric acid solution to separate solids.

However, operators initially faced challenges with incomplete dissolution. Investigations revealed that the issue stemmed from the carrier’s aluminum alloy rather than the fuel itself.

The engineering team responded by redesigning the carrier’s alloy to ensure faster dissolution, according to a press release from SRS.

“We identified that the carrier’s design was the bottleneck in the dissolution process,” said Tristan Downey, Spent Fuel Project Operations manager at Savannah River Nuclear Solutions (SRNS), the managing contractor at SRS. “By adjusting the alloy used in the carrier, we have significantly reduced the time it takes to process the fuel.”

The redesigned carriers are scheduled to be implemented before the next planned fuel transfer to H Canyon.

Nick Miller, deputy vice president for SRNS Environmental Operations, commended the team’s innovation, saying, “Our employees consistently partner to find improvements that enhance safety and efficiency. This change supports our processing goals and contributes to the continued success of HFIR research at Oak Ridge.”

Savannah River Nuclear Solutions, a Fluor and HII partnership, oversees the management and operations of the Department of Energy’s Savannah River Site, located near Aiken, South Carolina.