Syensqo, a spin-off of Belgian chemical company Solvay, celebrated the groundbreaking of its upcoming manufacturing facility at 3702 Clanton Road, Thursday morning, with great fanfare.

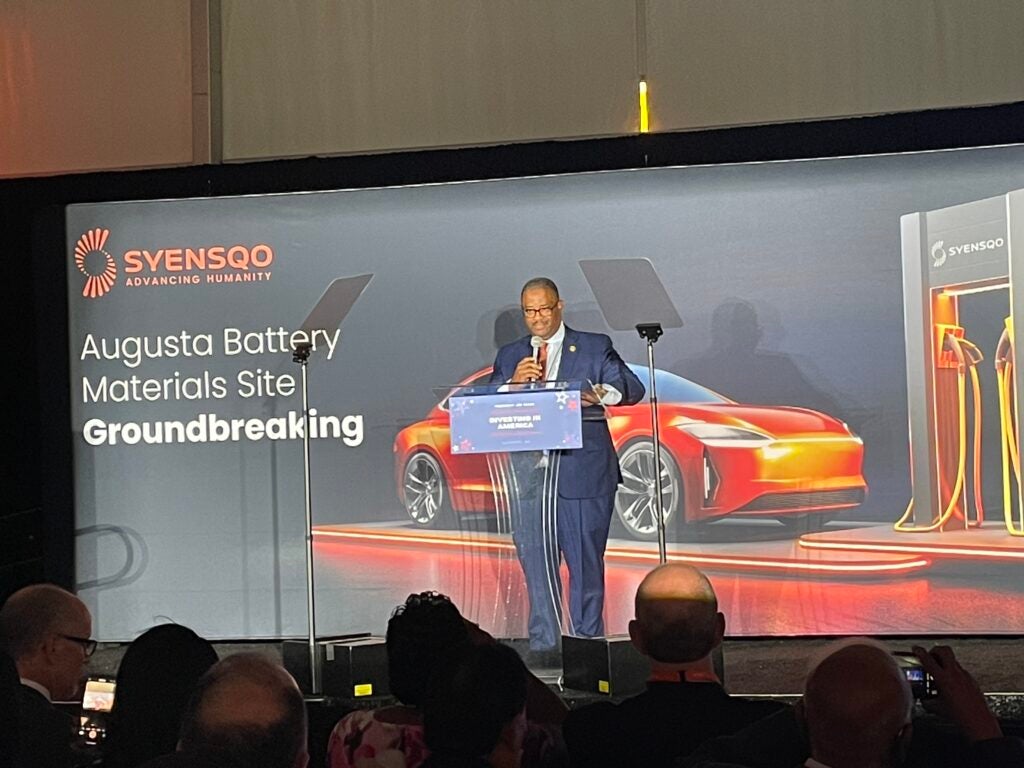

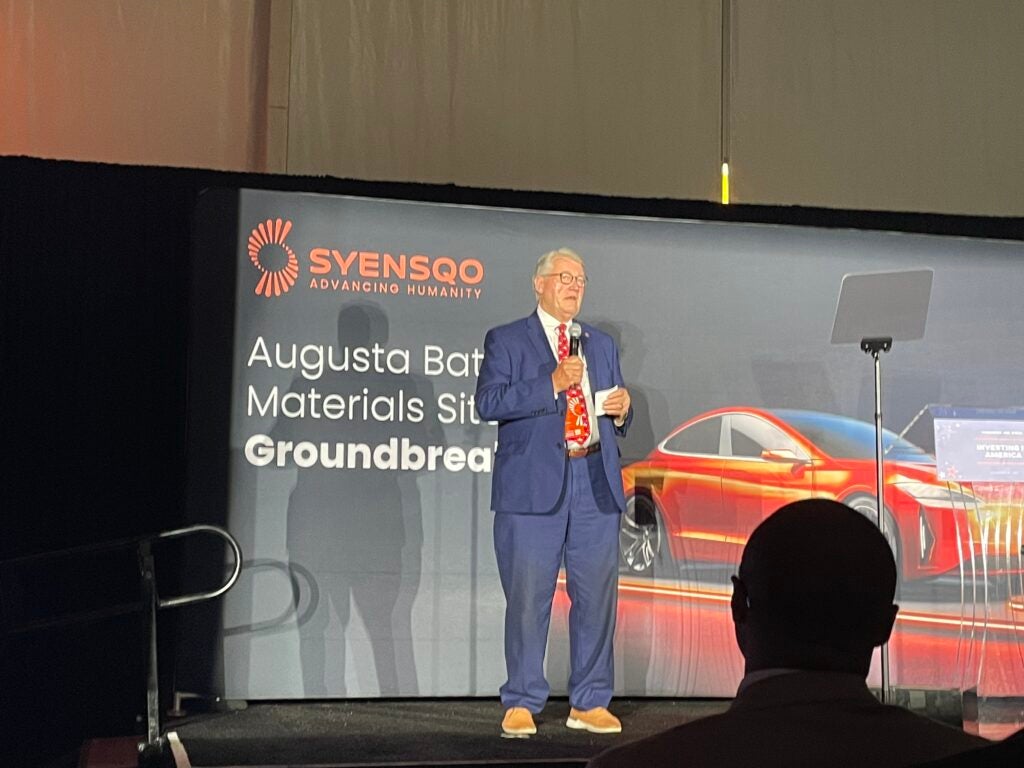

An elaborate affair that included several presentations and a catered lunch, the event welcomed guests including Augusta Mayor Garnett Johnson, 12th District Rep. Rick Allen and Augusta Economic Development Authority (AEDA) President Cal Wray, alongside a host of industry leaders.

Solvay Polymers bought the 61-acre Miracle Mile site, the location of its current Augusta plant, from BP Amoco in 2001. In early 2015, AEDA announced Solvay’s plans to invest $85 million in a new high-performance polymer plant adjacent to that facility.

In early 2023, Solvay received approval from the Augusta Commission for a special exception to build the plant, backed in part by $178 million in Bipartisan Infrastructure Law funds via the Department of Energy’s Office of Manufacturing and Energy Supply Chains.

In December of 2023, Solvay separated its materials and composites segment to form a new company, calling it Syensqo, a play on “Science Company.”

“You might also notice that the separation has shifted the company to be more US-centric,” said Syensqo CEO Ilham Kadri. “More than half of our manufacturing assets are here in the US, and while 50% of our workforce is dedicated to research and innovation, 10% is in the US.”

The new plant will produce polyvinylidene fluoride (PVDF), a polymer used to make electrode binders in lithium-ion batteries for electric vehicles (EV), helping extend battery life.

Syensqo is partnering with Mexican materials company Orbia to build the production facility, whose construction would run parallel with that of its sister construction site, Orbia’s raw material conversion plant in St. Gabriel, La.

Alongside the production of polymers like PVDF, lithium-ion sub-chemistries such as nickel manganese cobalt (NMC) and lithium iron phosphate (LFP) can provide energy density in batteries powerful enough to allow electric cars to travel upwards of 300 miles, explains Syensqo Chief Technology and Innovation Officer Mike Finelli.

“This is just the beginning of where this technology is going to go,” Finelli said, adding that Syensqo is working with companies to develop the next generations of EV batteries. Once the tech reaches what he refers to as a solid-state battery, which would allow for a range of 600 to 700 miles per charge. “The other advancement that’s happening… This allows you to charge your battery much faster.”

The Augusta site is expected to bring 100 jobs when completed, and some 500 — Kadri estimated up to 1,000 — construction jobs in the meantime.

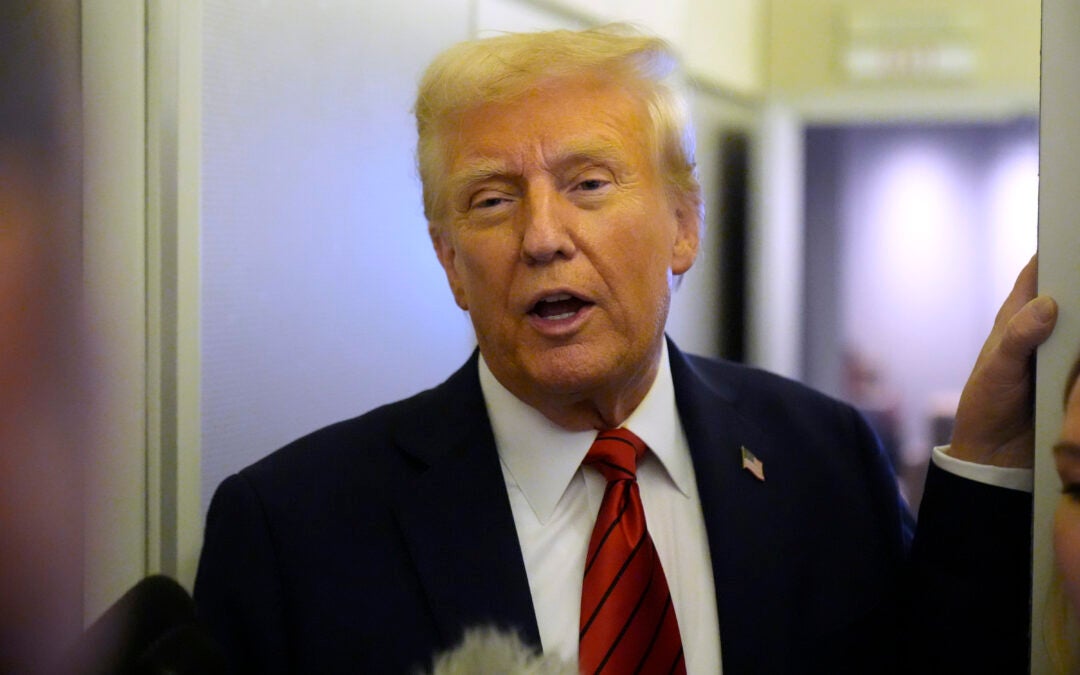

Tom Perez, senior advisor to President Joe Biden, lauded the potential workforce and infrastructure impact that the plant development represents.

“The $178 million that we are investing in here is a small percentage of what the total investment of the ecosystem will be.” said Perez. “Advancing opportunity is so critical, but we can’t advance opportunity if we don’t invest in opportunity for everyone to have a good middle-class job. And that’s what these investments are about… the intersectionality of the workforce hubs in these investments in clean energy, these investments in other technologies that are going to provide jobs here in Augusta and across the state of Georgia.”

Syensqo also plans to contribute $1 million toward workforce development projects in the CSRA. One of these projects is a mobile training lab for Augusta Technical College students. The donation is also to entail a commitment to hire local talent, supplemented by tuition aid.

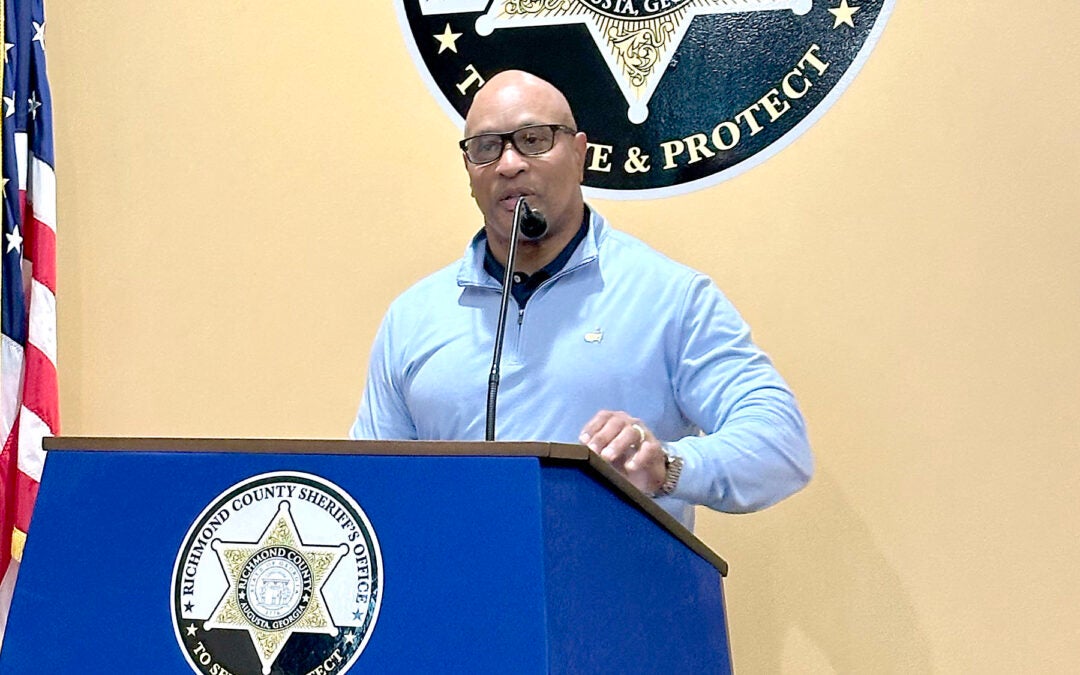

Augusta Tech President Jermaine Whirl cites Governor Brian Kemp’s aim to make Georgia the EV capitol of the U.S. for Augusta’s rigorous economic development strategies drawing EV manufacturing and supply chain industry to the area. He also notes Augusta’s unique resources, such as its proximity to the water and to Plant Vogtle, and its labor force.

“That’s why Syensqo came here, not just because of the incentives, but more importantly because of the talent and the talent that’s being developed,” said Whirl. “For us, that allows us to better recruit, because I can tell young men and young women to say if you come here, this company is hiring 100, 200 people, you’re going to have job opportunities.”

Construction of the new Syensqo polymer manufacturing facility is expected to be complete in three years.

Skyler Q. Andrews is a staff reporter for The Augusta Press. Reach him at skyler@theaugustapress.com.